Precision Air & Gas Control Valves

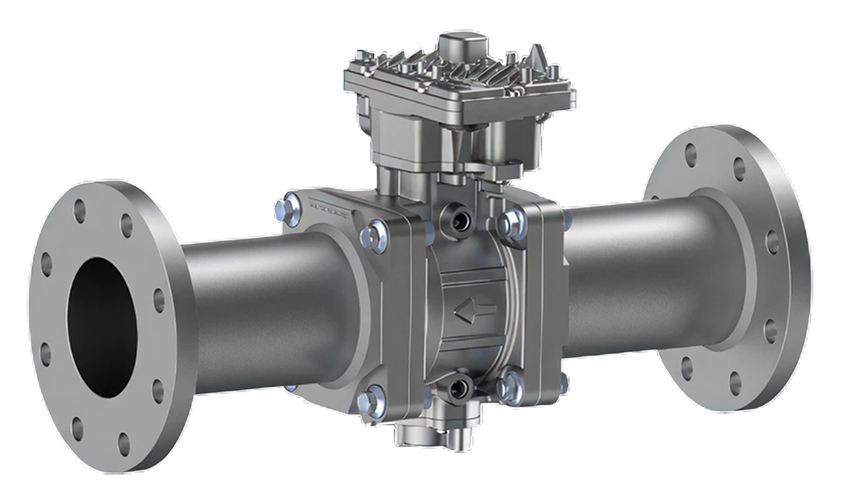

EControls’ Air and Gas Control Valves deliver precise regulation for natural gas, LPG, biogas, H2 blends, and alternative fuel engines—optimizing combustion, boosting efficiency, and minimizing emissions. Designed for power generation, oil & gas, and CHP (combined heat and power) applications, our valves meet the industry’s highest demands for performance and reliability.

Engineered for Performance & Reliability

Precise Control – Maintain optimal air-fuel ratios for maximum efficiency and emissions compliance.

Rugged Durability – Built to perform under extreme temperatures, vibration, and harsh operating conditions.

Seamless Integration – Easily adapts to modern engine management systems.

Maximum Uptime – Durable construction reduces maintenance needs and downtime, supporting continuous operation.

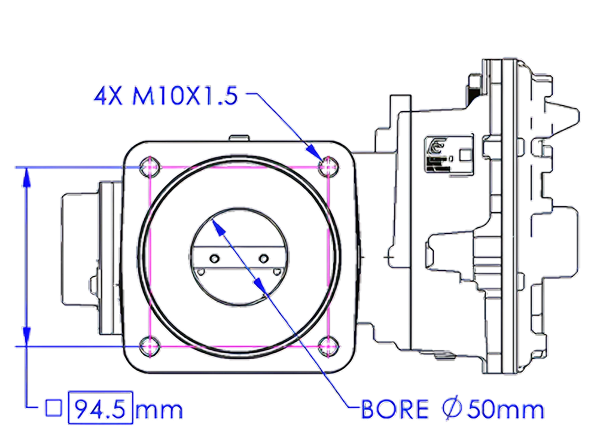

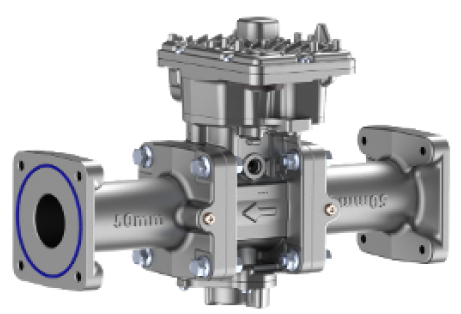

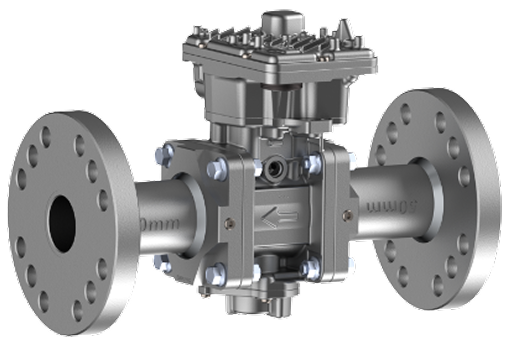

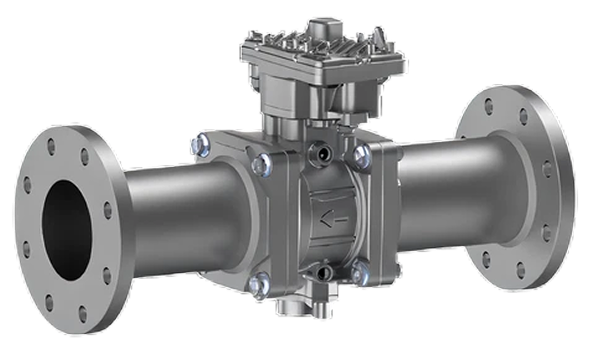

MFG 50

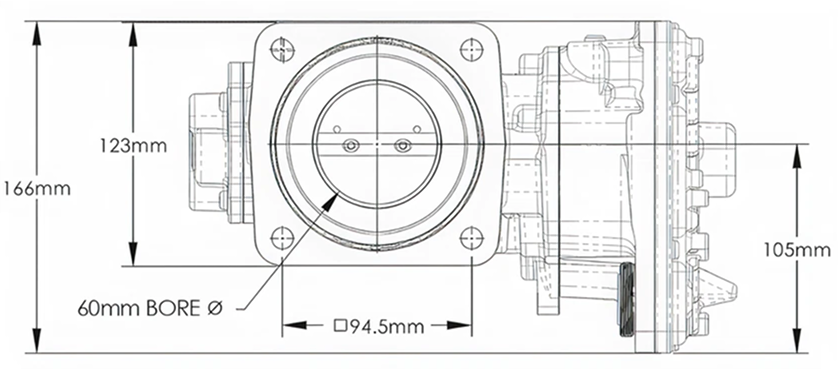

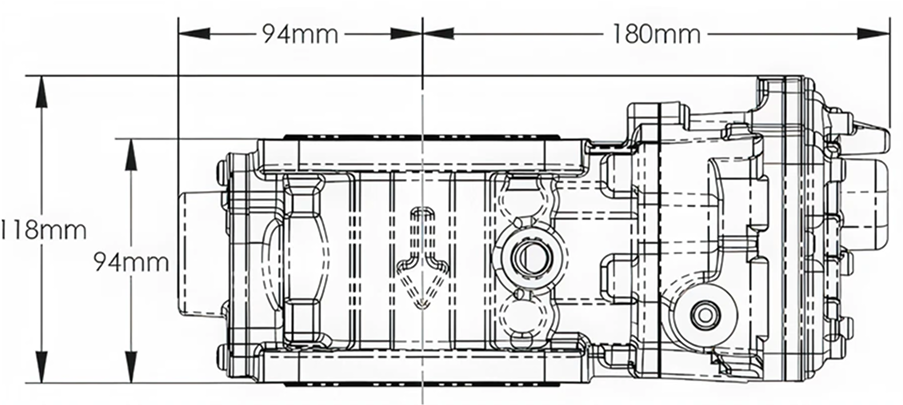

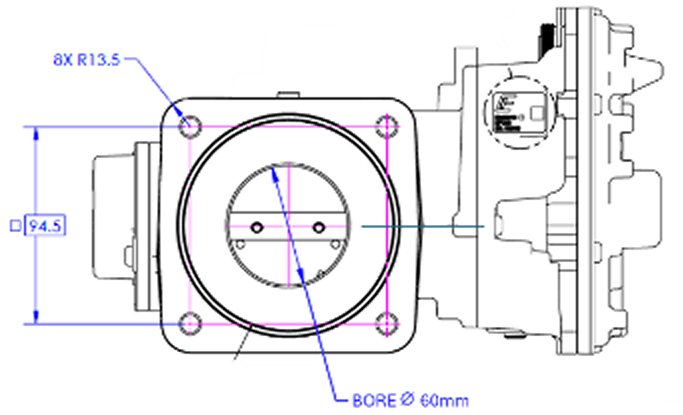

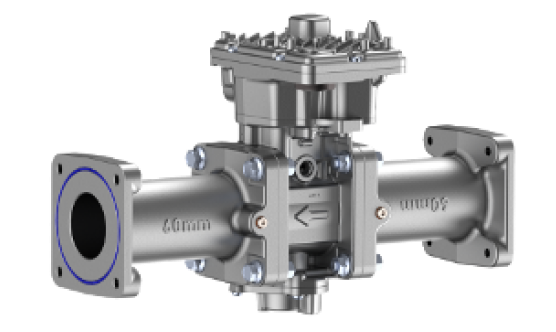

MFG 60

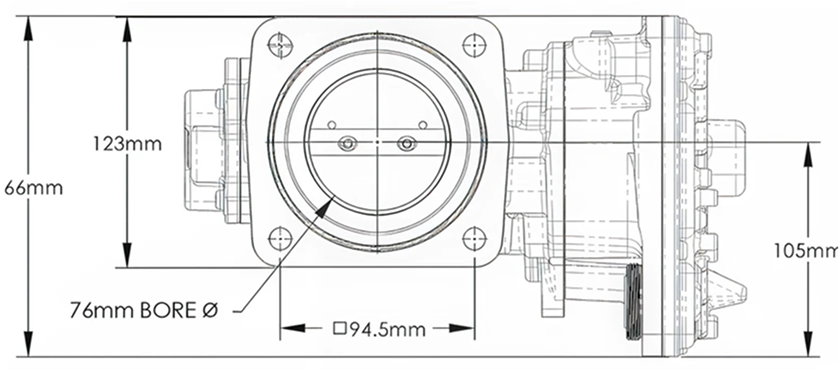

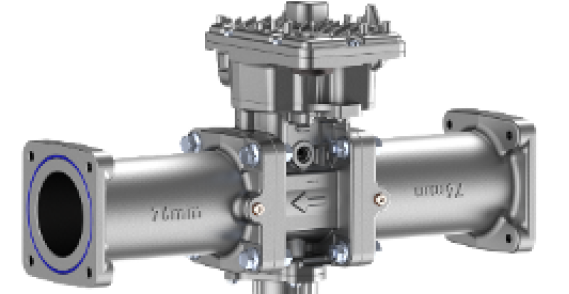

MFG 76

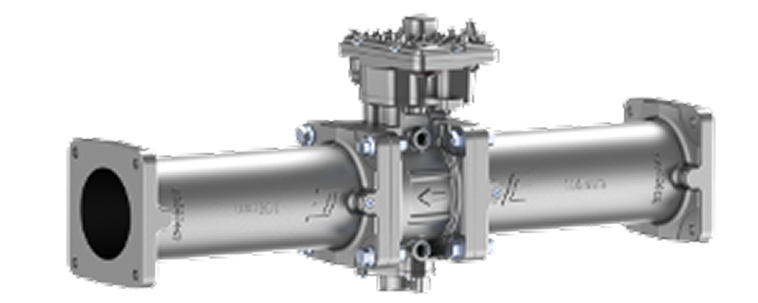

MFG 105

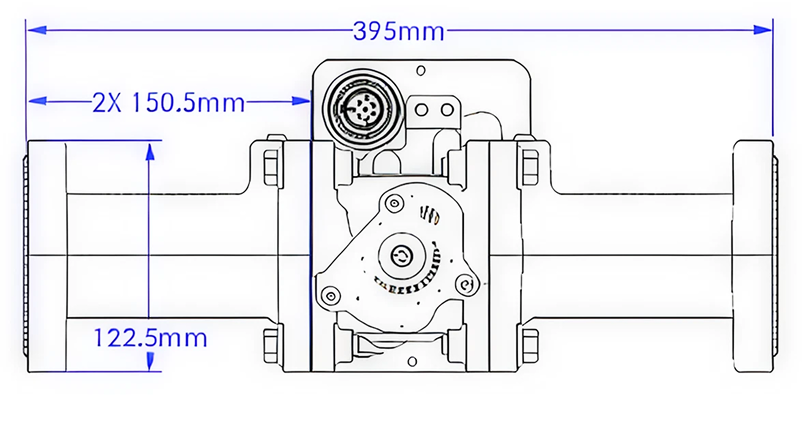

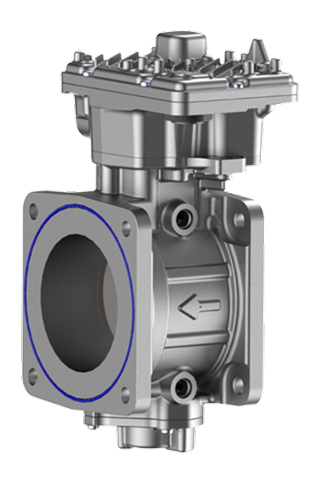

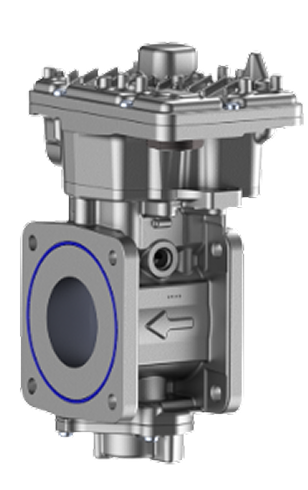

MFG -FR-50

TecJet™ Replacement

MFG -FR-105

TecJet™ Replacement

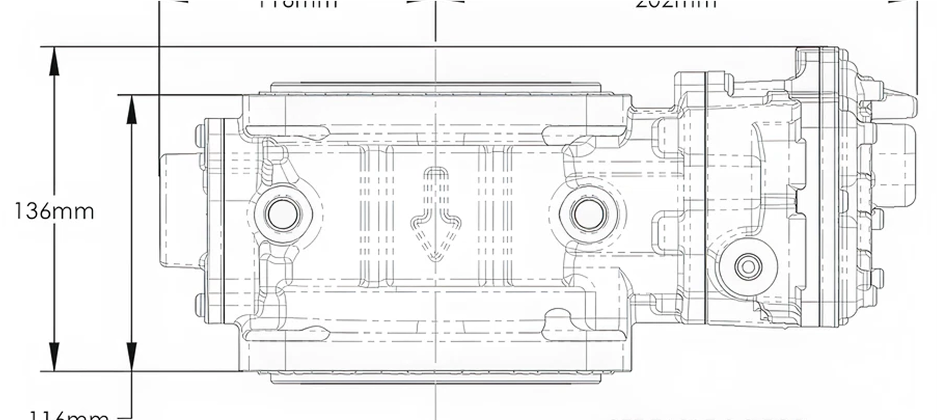

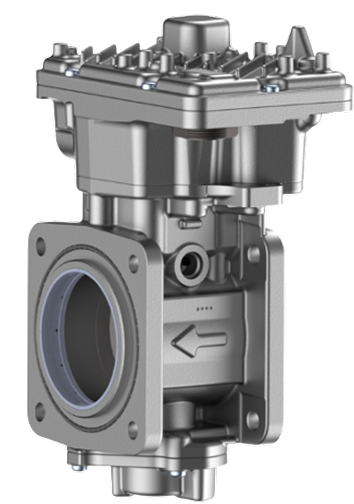

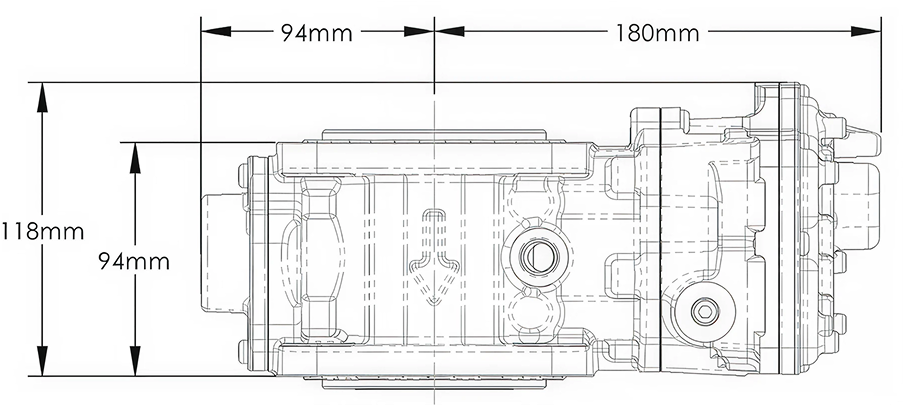

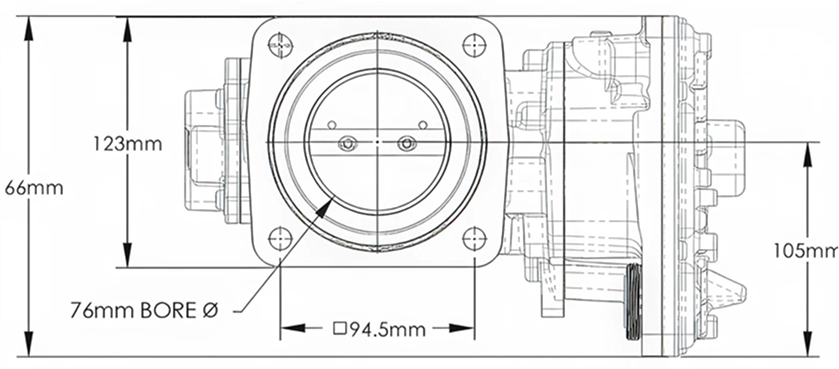

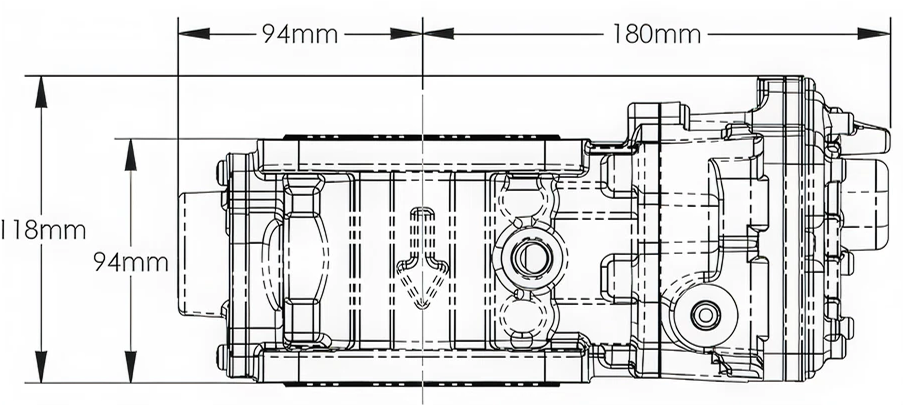

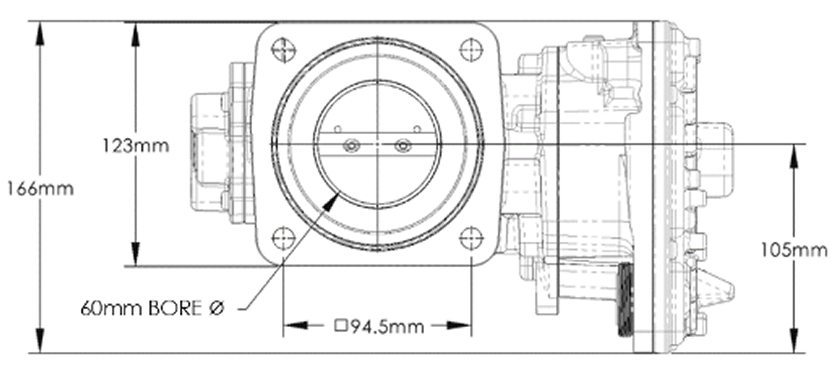

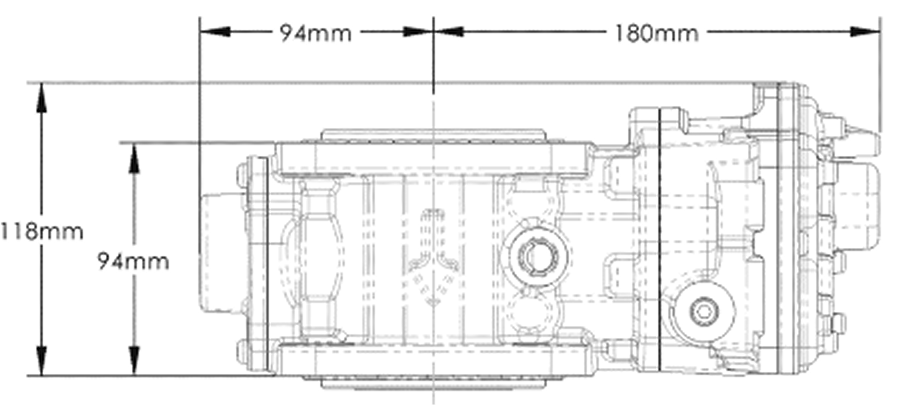

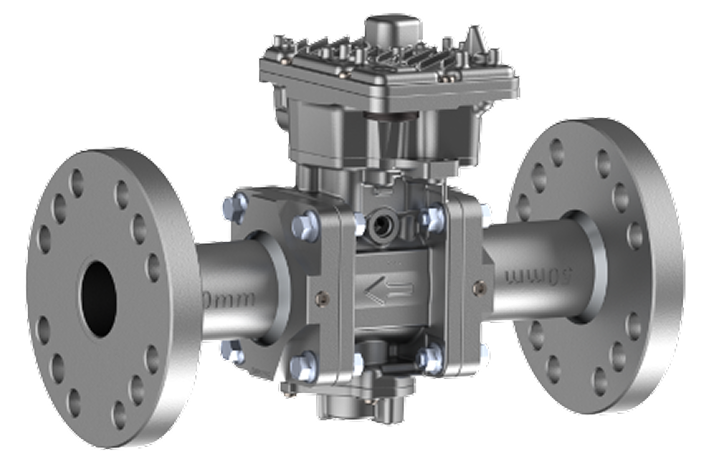

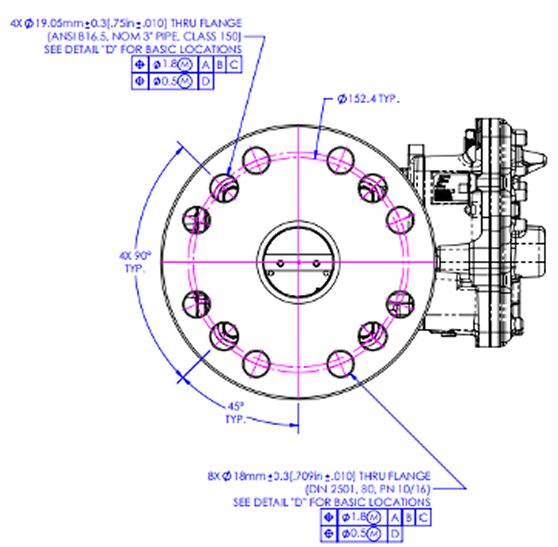

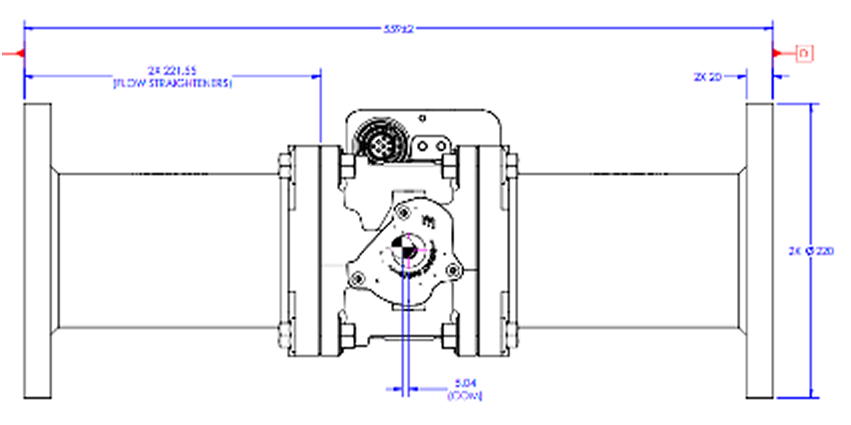

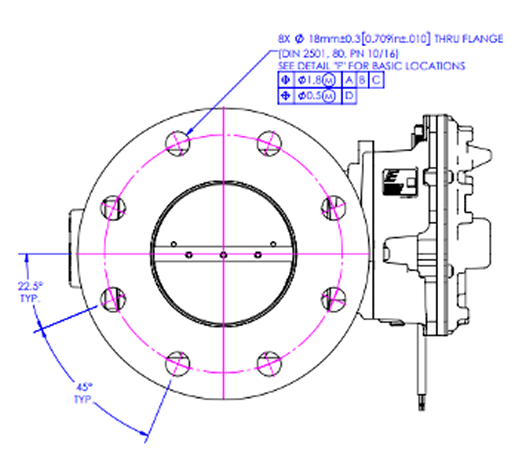

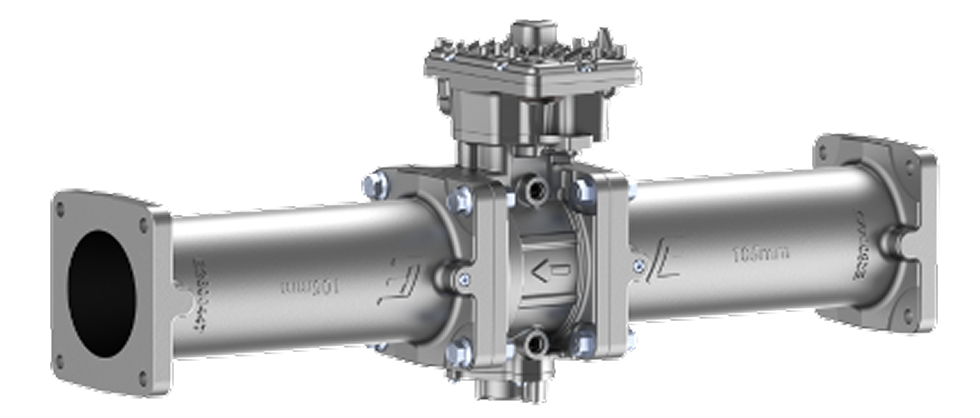

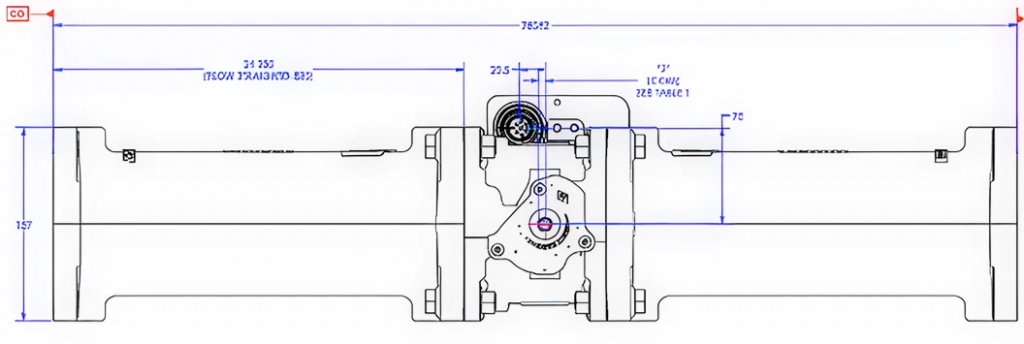

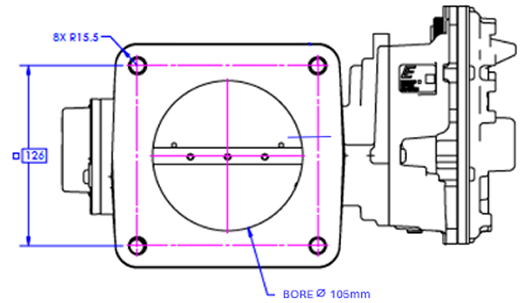

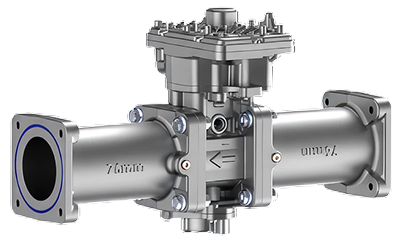

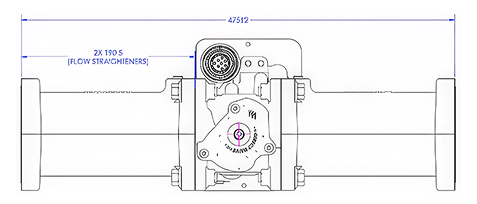

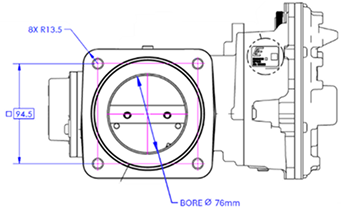

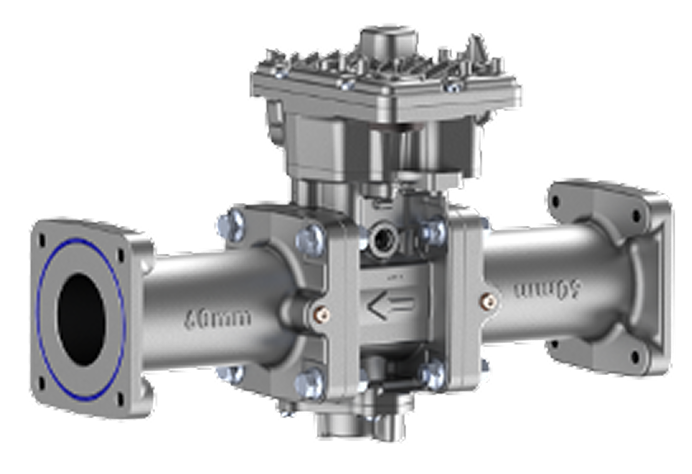

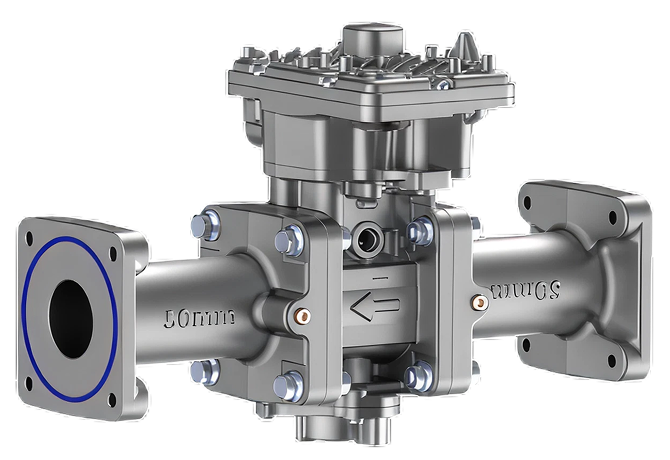

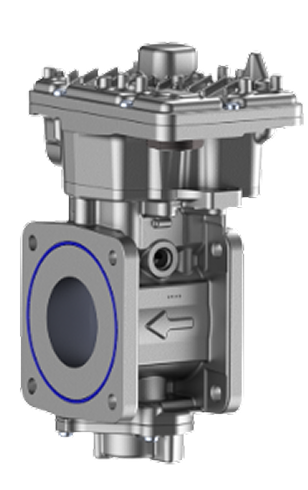

Mass Flow Gas Valves

When consistent, accurate fuel delivery matters most, EControls’ Mass Flow Gas Valves (MFG) set the standard. Available in 50mm, 60mm, 76mm, and 105mm sizes, the MFG series ensures stable fueling across a wide range of applications. Integrated pressure and temperature sensors provide real-time data for seamless engine control and diagnostics. The MFG is compatible with a wide range of engine management systems, making it a versatile choice for both EControls and third-party platforms.

The MFG-FR (Mass Flow Valve Field Replacement) offers the same performance with a field-replacement design that directly replaces the Woodward TecJet™—no system redesign required. Ideal for retrofits, the MFG-FR integrates easily into existing engines using various control systems.

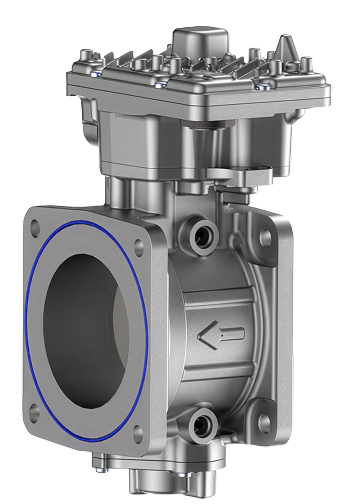

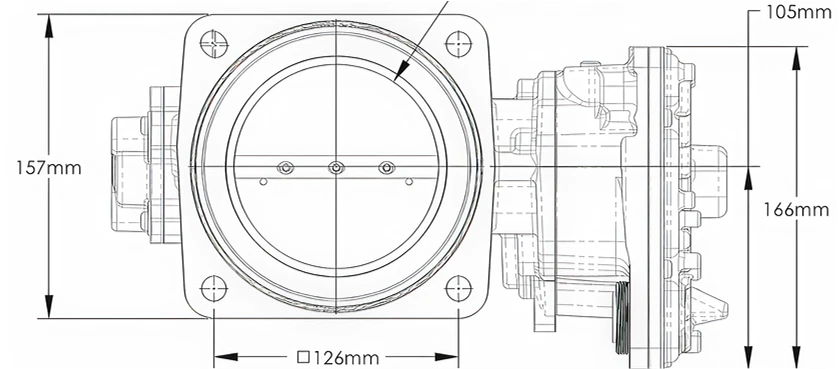

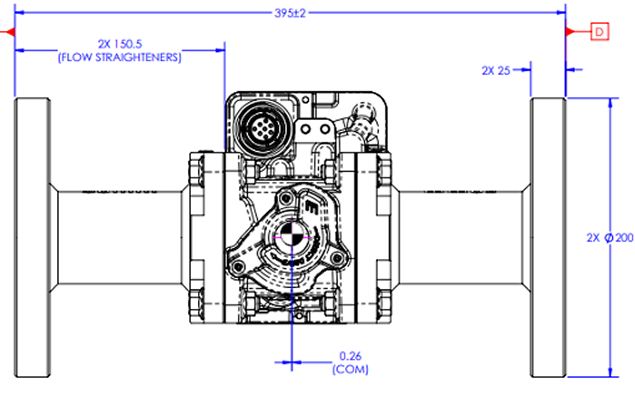

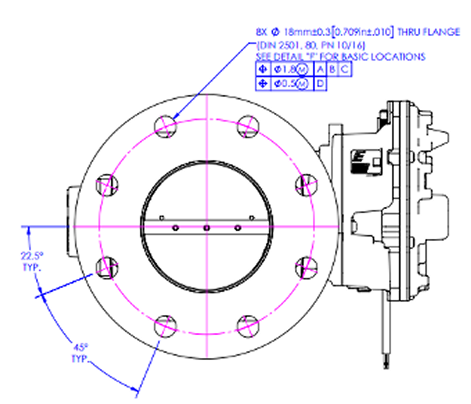

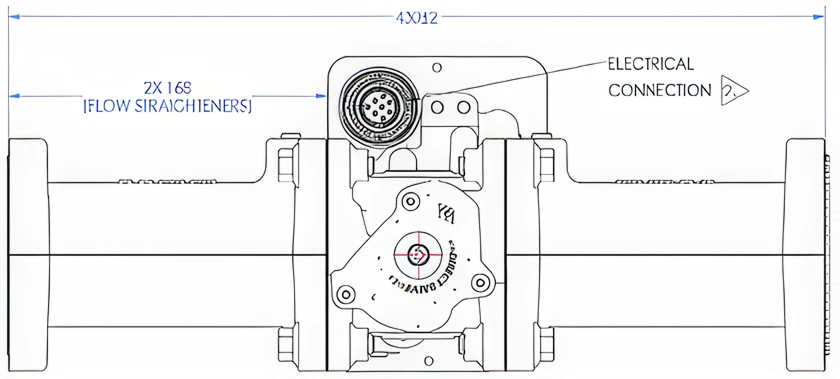

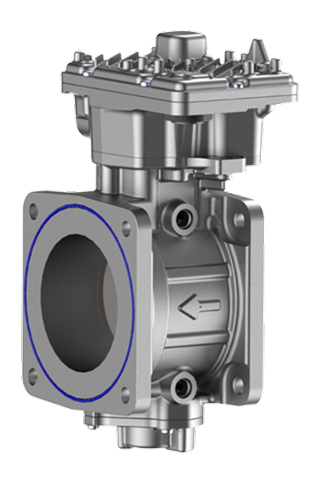

Air Control Valves

Available in 60mm, 76mm, and 105mm sizes, EControls’ Air Control Valves provide accurate airflow management to support stable combustion and precise fuel control in a wide range of engine systems.

MFA Series – Designed to measure actual air mass flow with high precision, outperforming traditional speed-density algorithms. When paired with the MFG gas valve, the result is exceptionally tight air-fuel ratio control—ideal for applications requiring stringent emissions performance, real-time feedback, and dynamic engine management.

AT Series – A position-controlled throttle operated via CAN interface, used where traditional airflow modulation is required. Perfect for systems that use ECU-commanded throttle position control and need reliable, robust valve performance in a rugged package.

MFA 60

MFA 76

MFA 105

MFA 120

AT 60

AT 76

AT 105

TecJet™ is a registered trademark of Woodward, Inc. EControls is not affiliated with, sponsored by, or endorsed by Woodward Inc.